We Make RecoverySandblastingNitridingStraighteningNormalizingCarbonitridingCarburizing

For over 60 years we’ve developed and applied technologies for heat treatment on behalf of third parties through specific processes dedicated to all the mechanical sectors that made us able to satisfy the requests of medium or large-scale products.

T.T.M. has developed and implemented high skills in the Thermal Treatments of Metals in the following sectors: mechanical, chemical, food, textiles, naval, aeronautics, tooling and automotive.

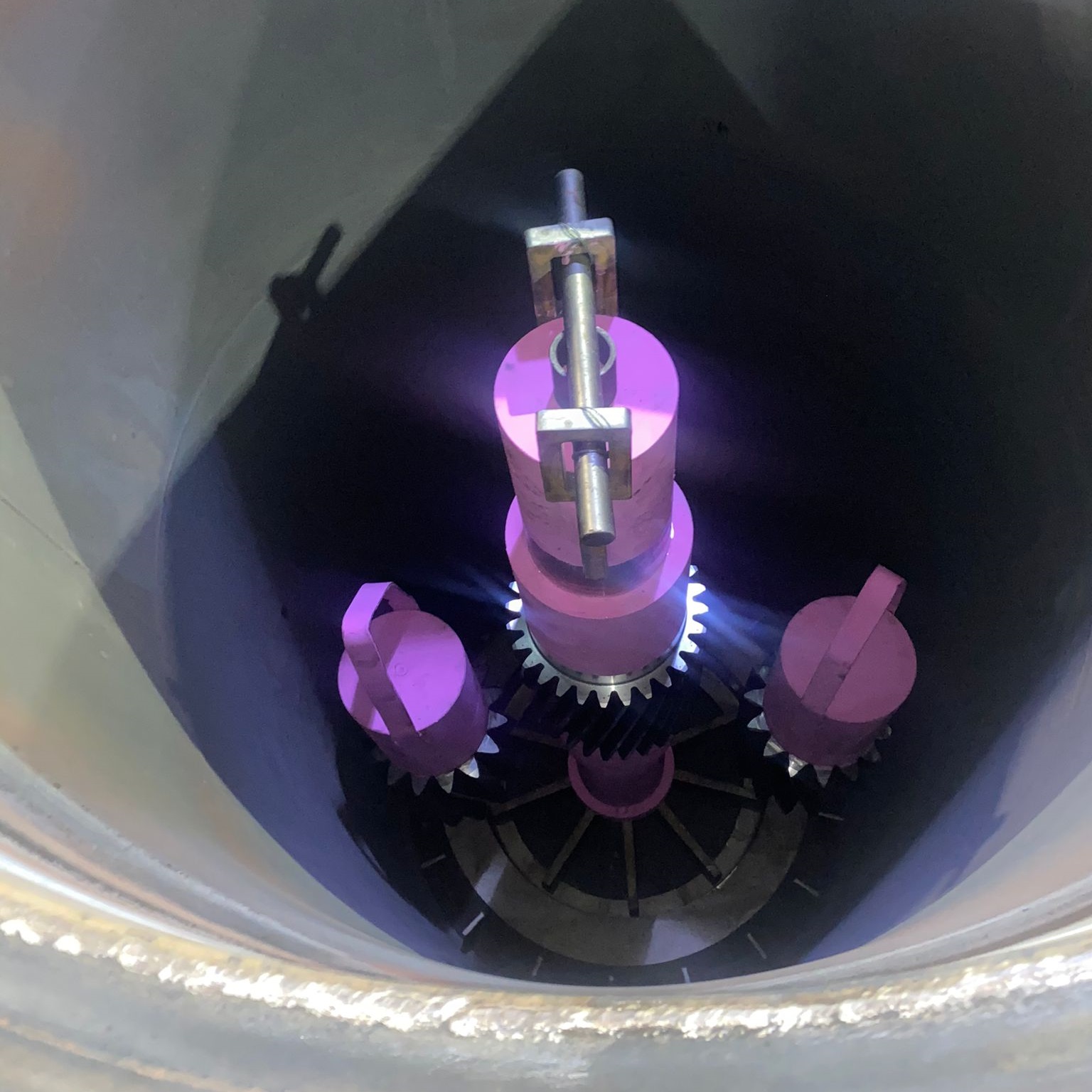

Our Plants

Who we are and the company

TTM s.r.l. is a metal heat treatments family-owned business founded in 1960.

It is located in Castellanza, in the province of Varese and it is extended to an area of 3700 square meters of which 1400 are covered.

For over 60 years we’ve developed and applied technologies for heat treatment on behalf of third parties through specific processes dedicated to all the mechanical sectors that made us able to satisfy the requests of medium or large-scale products.

T.T.M. has developed and implemented high skills in the Thermal Treatments of Metals in the following sectors: mechanical, chemical, food, textiles, naval, aeronautics, tooling and automotive.

T.T.M. is environmentally conscious

The use of monitored vacuum and filtration systems allows us to decrease the amount of fumes generated during the hardening operations.

A strictly closed cooling water recirculation system circuit allows us to save a significant amount of this precious element.

In addition, to fulfil the rules regarding noise pollution, we have installed soundproofing isolation systems.

More information

Quality certified UNI EN ISO 9001:2015

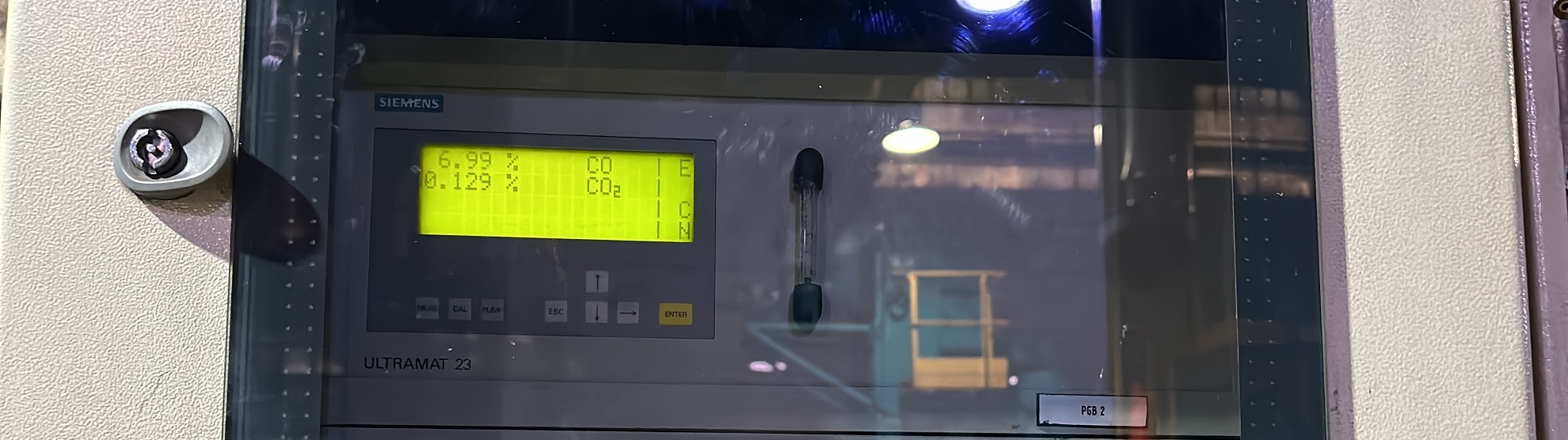

An T.T.M. the quality control is implemented throughout the whole production cycle, which is constantly supervised by electronic controls of the temperatures and of used atmospheres.

The check of the different steps of the processes is carried out through the specimens of the charges and/or directly over the customer's piece.

Here at T.T.M. we use our internal laboratory equipped with modern equipment that make us able to carry out all the final inspection control.

We can also provide certificates or consultations upon request.

T.T.M. is certified UNI EN ISO 9001:2015.

We can also provide certificates or consultations upon request.

TTM srl è certificata UNI EN ISO 9001:2015.

“We have been working with TTM for more than 15 years with mutual satisfaction. We know that we can use a capable and competent partner with high level technical knowledge, but also with the flexibility and adaptability of a small family business. We recognize in TTM a company inclined to invest in the future, the test is the achievement of ISO9001:2015 certification, reached in September 2018.”

Company serious, expert, helpful. Fast answer and deliveries. Professional and at the same time simple and cordial. Great!

Company where the costumer care still has value and these days. Fast in the answers and always ready to give suggestions to get the best possible result.